You’re here because your Smart-UPS, Symmetra, or Galaxy just threw a warning, or you’ve got a Canadian tender deadline coming up and can’t risk missing a key maintenance spec. Skip the fluff—let’s make sure you get a full, field-tested preventive maintenance (PM) scope and checklist that will keep you off unplanned bypass, tick the compliance boxes, and convince procurement and IT that you’re covered. We see this every week: missed PM steps and generic scope docs leave critical systems vulnerable, especially in Canada where environments can be harsh and regulations matter.

Below, you’ll find a copy-paste template for tenders and SLAs, plus a real PM checklist for APC UPS systems. This is what APC Service Canada technicians rely on nationwide. It covers what you should demand for any maintenance contract—and what to confirm before letting anyone touch your system. We keep it practical, repeatable, and easy for risk review or a compliance audit.

Quick Scope: APC UPS PM Checklist for Canadian Tenders

| Check | Pass/Fail | Notes |

|---|---|---|

| Visual inspection (wiring, contacts, capacitors – no swelling/leakage, no discoloration) | ||

| Breakers/connections temp check (should be below 80°C under load) | ||

| Battery float voltage/current recorded, impedance checked | ||

| All fans operational and air filters clean | ||

| Phase-to-phase input/output voltages/currents within spec | ||

| Event log reviewed, firmware current | ||

| Room temperature/ventilation checked (20-25°C target) |

If any critical line fails, reschedule a full maintenance. If you’re running more than two ‘fail’ marks, your risk of going to bypass jumps quickly—and you’ll be facing an after-hours emergency call.

Complete Scope of Work Template to Copy (Canadian Context)

This template is what we use for Smart-UPS, Smart-UPS Online, Symmetra, and Galaxy units across Canada. Paste it into your RFP or contract, then adjust site-specific lines (access, battery types, spares, etc.).

1. UPS System Preventive Maintenance

- Visual inspection of all UPS and battery-related components: wiring harnesses, subassemblies, contacts, power and control cables, rectifier/inverter cards, static switch, capacitors (look for swelling, leakage, burnt marks).

- Check site conditions—room ventilation, ambient temp between 20° and 25°C, clear floor space front/rear (minimum 36″).

- Measure and record input/output/bypass voltages and currents for each phase. Check neutral/ground where accessible (contact us for any uncertainty—you don’t want to probe energized busbars).

- Tightness of electrical terminations by torque wrench, only by qualified APC technician. IR scan for hotspots if possible.

- Inspect and, if needed, clean or swap air filters. Confirm all fans are clean, spinning correctly, and not noisy.

- Review system event log and alarm history. Confirm last firmware revision level.

- With your supervisor’s sign-off, coordinate transfer to bypass and perform a partial runtime test (max 10 min at current load). Requires full maintenance window and staff on-site to monitor.

- Clean up exterior/interior as feasible, avoiding powered components unless in full lockout.

2. Battery Preventive Maintenance

- Check all RBC battery references—record model numbers (e.g., RBC123, RBC17, RBC43) and visible install/expiry dates.

- Visual for corrosion at terminals, cracks in cases, swelling, or leaking for all blocks/cartridges.

- Float voltage across entire string (should be within APC spec—most blocks: roughly 2.25–2.30V/cell for lead acid).

- Impedance test each block. If any block is more than 20% higher than string average, it’s flagged for replacement.

- Functional check of battery monitoring (if installed).

- Cables/terminations torque checked (typically 10–15 Nm for APC racks—verify for your model). Don’t torque live unless you’re factory-trained.

- Recommend full string replacement when battery age hits 3–5 years (or as local codes dictate).

3. Reporting

- PM report delivered, including full measurement logs, pre/post photos, technician notes on any failures or recommendations.

- Compliance with CSA C22.2, IEEE 450/1106 as applicable (if your SLA or tender requires Canadian standards).

- Technician must be APC-trained with several years’ experience on equipment of similar size.

- Proposed due date for next maintenance and/or replacement intervals (especially key for end-of-life battery alerts).

Step-by-Step: Booking a Safe, Zero-Downtime UPS Maintenance in Canada

Here’s how we coach you through a safe maintenance cycle (no guessing):

- Plan your window. Book 4–8 hours. We advise weekends or early morning for least impact. Confirm static or maintenance bypass powers the load before work starts.

- Prepare the area. Secure the site if it’s energized work—always use two-person rule, and have a supervisor or building tech on hand. Stock up on fuses, filters, and at least one spare RBC battery for swap if flagged.

- Send us the details below (see next section) so we land prepared.

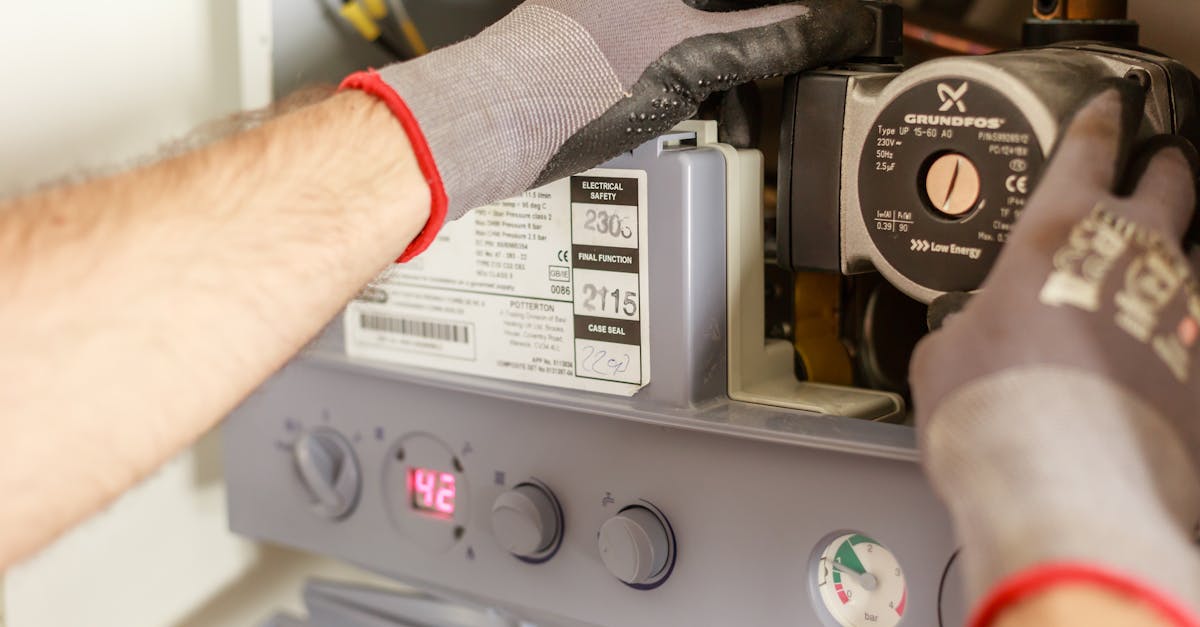

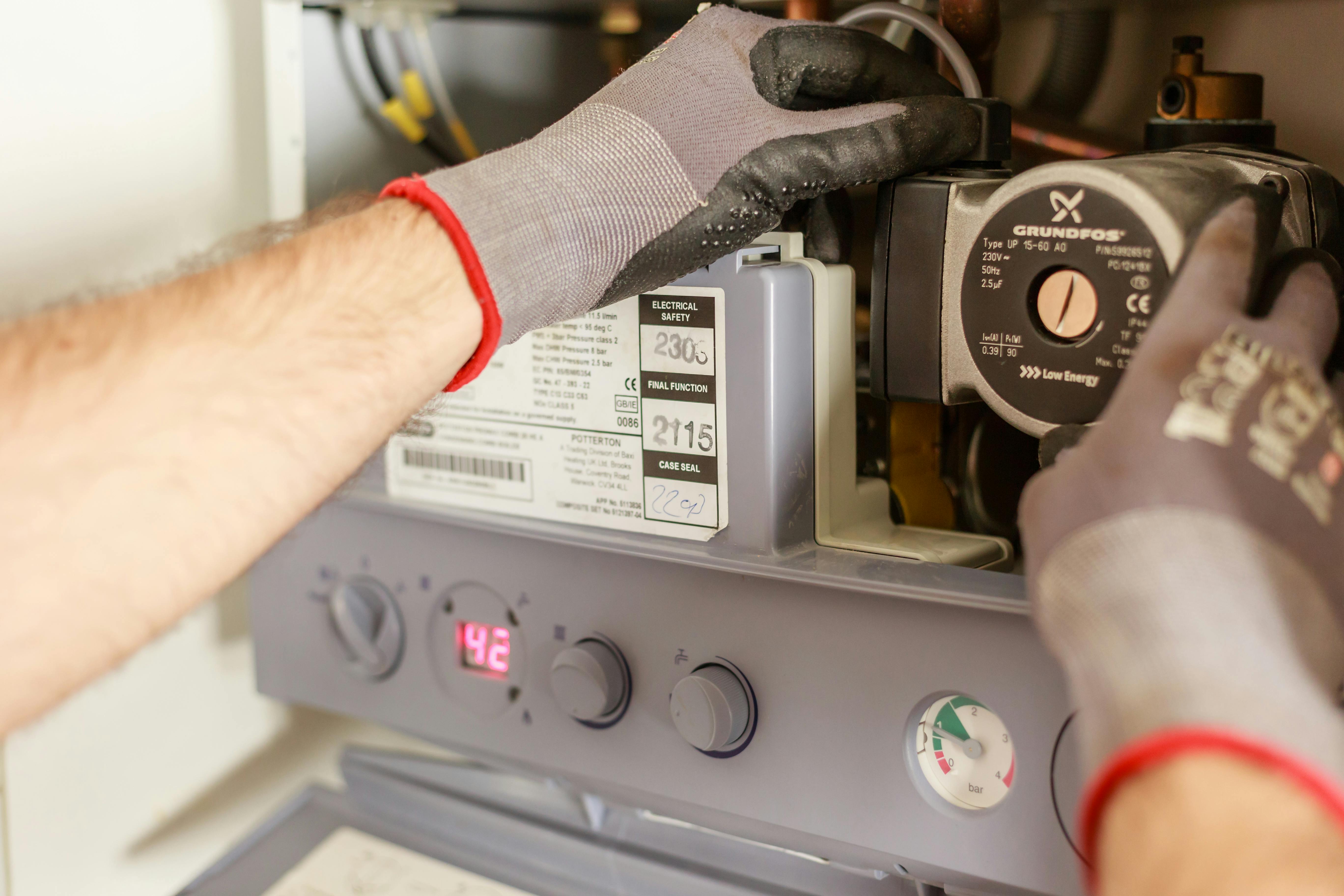

- During visit. Our technician arrives with tools, meters, and PPE. If an action requires opening up high-voltage internals, STOP—only our certified techs proceed (never your building staff or IT unless certified and authorized).

- After PM. We deliver a full audit-traceable report for your compliance binder, runtime stats, and recommendation for when to next book maintenance. If we find failing parts, you’ll get clear options. You should see less false alarms, fewer unplanned bypass events, and stronger system confidence right away.

For Procurement & Management: What to Document, Downtime Risks, and Planning

If you’re drafting the RFP or compiling the contract binder, these practical points go a long way with risk teams, auditors, and insurance.

- Downtime risk reduction. Regular PM by a competent APC specialist typically cuts unplanned outages by half or more, based on data from wider field service experience.

- Maintenance window and bypass. Never book without confirming bypass works and on-site generator is tested (especially in data centers or hospitals).

- Spares. Keep extra fuses, filters, and at least one genuine new RBC battery for every distinct Smart-UPS, Symmetra, or Galaxy model you operate. Flag the exact RBC type (see your last report, or pull from the UPS front panel or old battery).

- Site log and documentation. Retain every PM report—these satisfy regulatory inspections and keep lifecycle plans defensible.

- Contract best practice. Canada-wide, most contracts specify at least 2x/year PM, emergency support within 4 hours, and automatic battery replacement alerts every 3–5 years.

If you’re not sure about which parts to keep stocked, reach out—we’ll save you the scramble when a battery alarm hits.

What We Need From You to Quote or Book Service

- APC model + serial number (for example, SMT2200RM2U, Serial #AB1234X56)

- Current load (percent or watts, shown on the UPS display: e.g., 75% / 4000W)

- Specific symptoms, alarm message, or recent event log extracts

- Battery age or last replacement date (stamped on the battery or from your PM logs; e.g., RBC124 changed April 2023)

- Your site location, and any access constraints (business hours only, badge needed, after-hours required)

Text or email these details (photos help, too) to info@apcservicecanada.com or call 1 (438) 881-3363. We quote or schedule same day, and almost always within two hours. Faster info means a faster response.

FAQ: Preventive Maintenance and APC UPS Systems in Canada

How often should I schedule preventive maintenance for my APC UPS?

For most Smart-UPS, Symmetra, and Galaxy units, we advise maintenance at least twice a year. Environments with more dust, heat, or cycling loads benefit from quarterly checks. Always follow your specific model’s manual and CSA/IEEE guidelines.

Can I do basic visual checks myself?

Yes, you can safely check for warning lights, dust buildup, blocked airflow, or odd noises on the exterior. For voltage, battery impedance, or any internal component checks, only allow a qualified technician. Never open the enclosure or battery cabinet unless trained and authorized for electrical work.

What are typical symptoms that require immediate service?

Persistent battery alarms, random shutdowns, “replace battery” lights that won’t clear (see this troubleshooting post), overheating warnings, or repeated transfers to bypass. If in doubt, request a runtime check or PM visit.

How do I identify or order the correct APC battery cartridge?

The RBC (Replace Battery Cartridge) number is typically on the front of the existing cartridge or in the PM report. If you’re unsure, send us the UPS model/serial number—we’ll identify and quote the correct SKU for you.

Does preventive maintenance void my manufacturer’s warranty?

No–as long as it’s performed according to APC guidelines, by certified technicians, and documented thoroughly. In fact, you may be required to keep regular PM logs to maintain warranty support.

What happens during a runtime test?

With your approval during a maintenance window, we simulate a partial utility failure and track how long your batteries support the protected load. It confirms battery health and helps you plan replacements before the system is at risk.

Summary: Why Choose APC Service Canada for Your PM, Tender or SLA

Preventive maintenance on your APC UPS isn’t busywork—it’s the most effective way to slash unplanned bypass, extend battery life, and keep your compliance bulletproof for auditors or insurance requests. We see failures every week from missed or generic PMs. Our technicians across Canada bring manufacturer-level expertise on Smart-UPS, Symmetra, and Galaxy, backed by clear reporting and up-to-date battery handling.

When you need audit-grade maintenance, zero-worry battery swaps, or help writing compliant tender scopes, visit gdftech.com or call our team. We’ll save you downtime and hassles—and you’ll get the paperwork and runtime confidence your site needs. For next steps, get a quote, schedule a PM, or ask for a no-hassle runtime check today.

Related reading: How regular maintenance reduces downtime and costs | How often should you replace batteries?